Improving Business and Technology through Efficiency and Simplicity

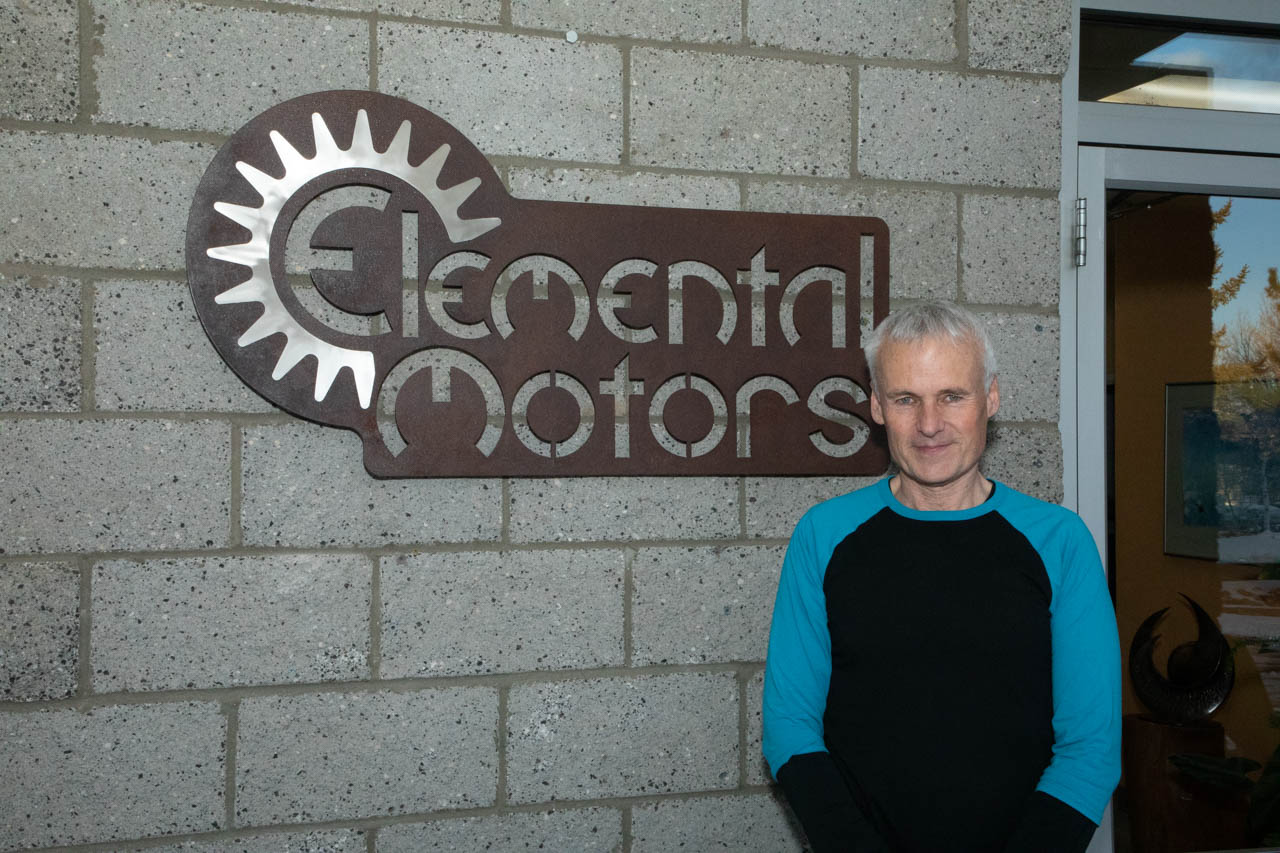

David Calley believes in efficiency. To him, the power of an efficient system is in its ability to create space and time for human creativity and innovation. A physicist and sculptor by education and a tinkerer by nature, it’s no surprise that at his current business, Elemental Motors, Calley is working to redesign one of the most widely used pieces of human technology—an electric motor—to become more efficient than anyone dreamed possible.

Quantum Flux Motors

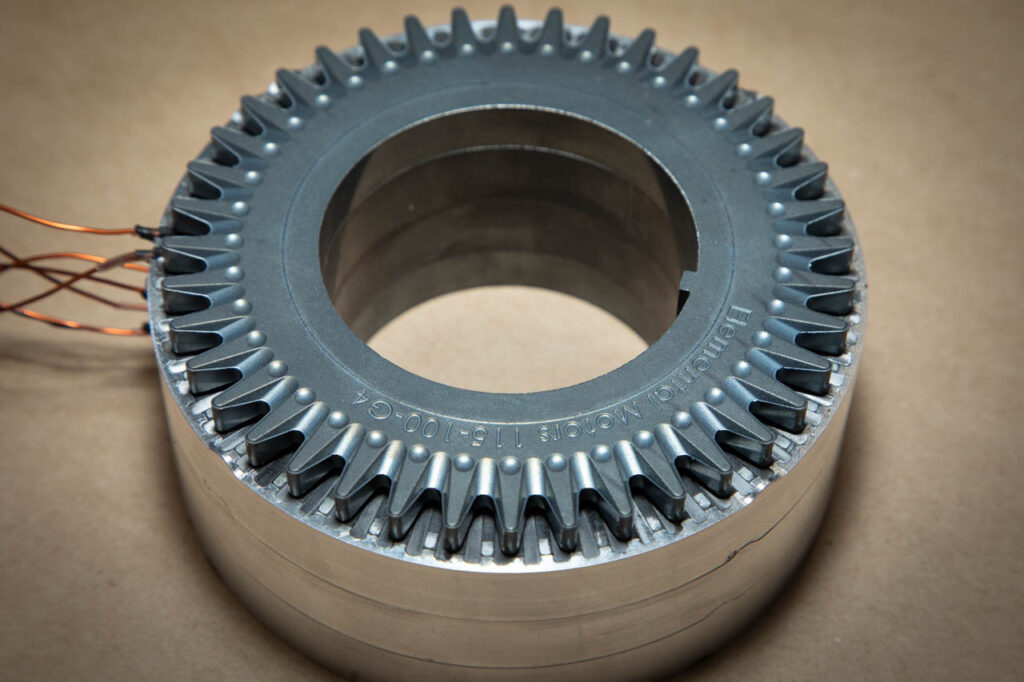

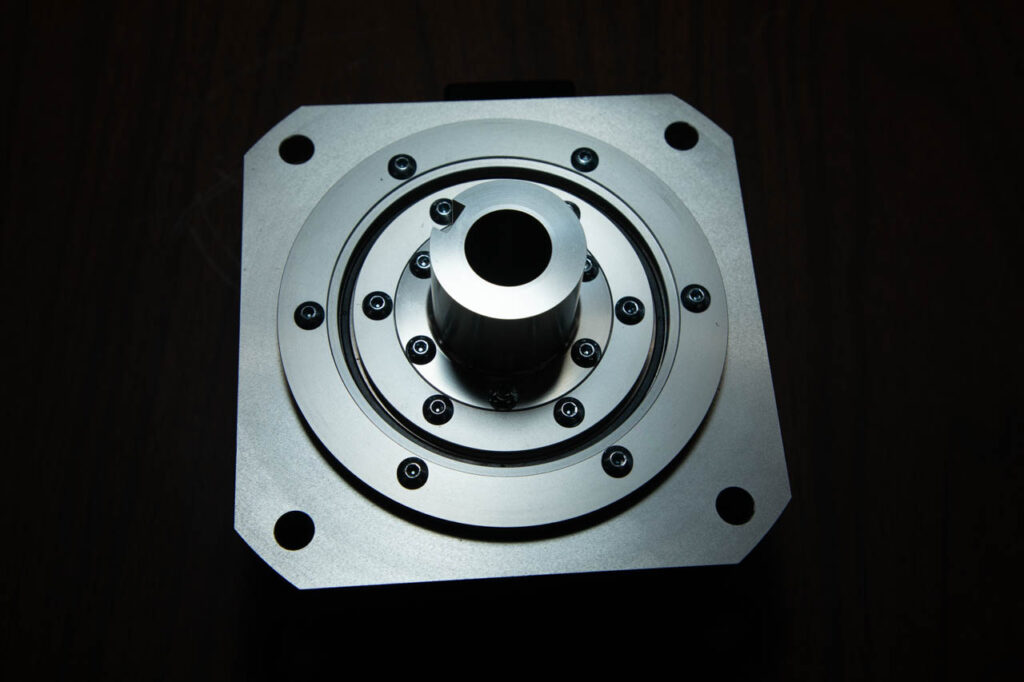

Now in its 4th generation of design, Calley’s “quantum flux” motor stands apart from a traditional electric servo motor. Instead of a complex assembly of individual parts, which by nature involves a substantial amount of energy loss, this new motor design uses a single piece of pressed iron powder called “soft magnetic composite” shaped in a way that allows it to operate with the power of a much larger motor. One of Calley’s mid-sized quantum flux motors fits easily in your hand and weighs only about 5 lbs, but has capability comparable to a 100 lb traditional motor.

Now in its 4th generation of design, Calley’s “quantum flux” motor stands apart from a traditional electric servo motor. Instead of a complex assembly of individual parts, which by nature involves a substantial amount of energy loss, this new motor design uses a single piece of pressed iron powder called “soft magnetic composite” shaped in a way that allows it to operate with the power of a much larger motor. One of Calley’s mid-sized quantum flux motors fits easily in your hand and weighs only about 5 lbs, but has capability comparable to a 100 lb traditional motor.

This motor’s size, design, and capability eliminate the need for other components such as gear boxes and fans that are typically used in conjunction with a motor. This means that equipment using a quantum flux motor will not only be much lighter, but also will have fewer components that could potentially become failure points. According to Calley, “When you can shrink all of your equipment and it’s lighter, you can do more.”

Calley is excited to experiment with all the different applications these motors may have. Looking around his shop, one can see his motors being put to work replacing the hydraulic controls used in forklift attachments and replacing the electric motor on a dirt bike prototype among other projects. David would also love to see his motors put to eventual use in transportation and aviation. For now, they are available for purchase through his website for individuals and companies to use as they wish. Some of these purchased motors are now in use in electric boats and agricultural robots.

Better for the Planet, Better for People

In addition to being lighter, smaller, and more powerful than other electric motors, Calley’s quantum flux design uses substantially fewer raw materials—about one tenth of the copper, iron, and rare earth magnets. If this type of design is able to gain popularity in the market, it means making electric technology less resource intensive. Less resource use means less mining, and it also makes a transition to electric infrastructure that much more attainable.

In addition to being lighter, smaller, and more powerful than other electric motors, Calley’s quantum flux design uses substantially fewer raw materials—about one tenth of the copper, iron, and rare earth magnets. If this type of design is able to gain popularity in the market, it means making electric technology less resource intensive. Less resource use means less mining, and it also makes a transition to electric infrastructure that much more attainable.

Calley and his Elemental Motors team are also working on refining and automating the motor assembly process with the goal of freeing the human engineers working there to spend their time and energy on more creative and complex pursuits. Regarding manufacturing, Calley’s objective is to make the process “embarrassingly simple.” His motto: “Keep on it until you’ve reduced it to a dumb machine. It’s not worthy of human beings.”

Calley’s interest in making things better for humans extends far beyond the team he’s assembled to work with him. Rather than being driven by the potential profit his project could produce, he talks of the better world this technology could contribute to: “I don’t want any more to do with money than I have to. I want to do things that make it better for people.”

Business in Flagstaff

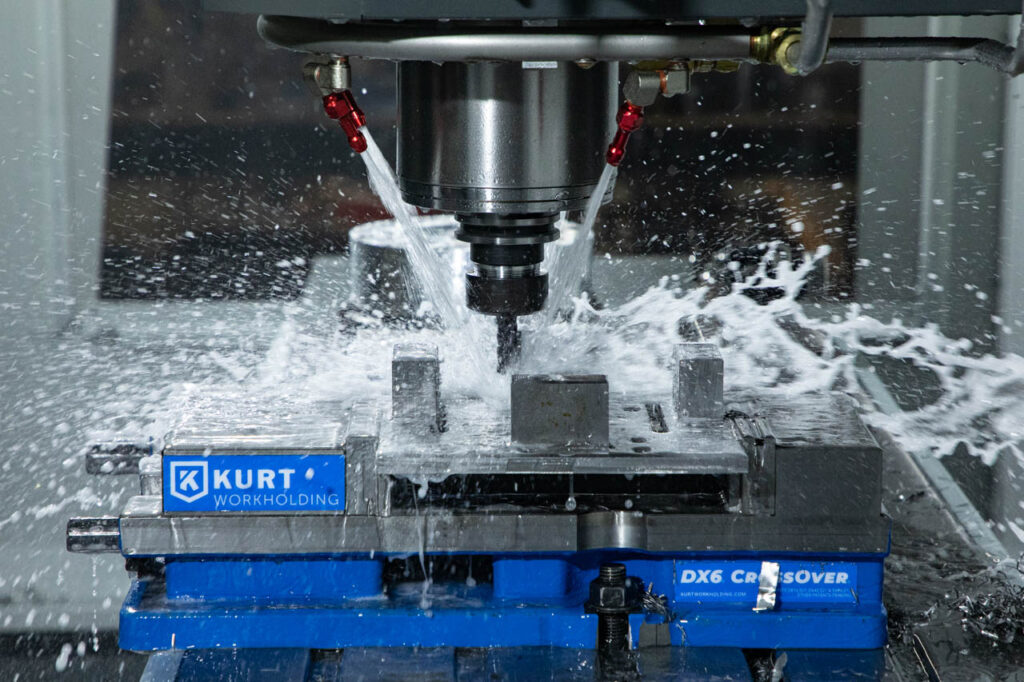

Although profit is not the driving force behind Calley’s work, Elemental Motors is set up to succeed financially. Presently, the company is still a startup, having been established in 2019 and acquired patents in early 2020. The business only recently acquired a 3rd CNC machine that’s been put to work fabricating components for the motor assembly machine the team is working on. Calley admits that during this phase, “It all feels theoretical,” but he expects the work to be fully supported by customer sales in the 3rd or 4th quarter of 2023.

According to Calley, there are pros and cons to starting this type of manufacturing endeavor in Flagstaff. He notes  that manufacturing culture here as compared with somewhere like Shenzhen in China is simply not as quick and efficient, which means having to spend more time and money having components made and shipped. Calley offsets some of that cost by being “extremely vertically integrated.” The Elemental Motors team creates as much as they can in house, but it’s not just about avoiding the challenges that come with outsourcing some of the work. Instead, Calley notes that understanding how every piece is created and how all those pieces work together helps him and his team create better design.

that manufacturing culture here as compared with somewhere like Shenzhen in China is simply not as quick and efficient, which means having to spend more time and money having components made and shipped. Calley offsets some of that cost by being “extremely vertically integrated.” The Elemental Motors team creates as much as they can in house, but it’s not just about avoiding the challenges that come with outsourcing some of the work. Instead, Calley notes that understanding how every piece is created and how all those pieces work together helps him and his team create better design.

One of the major pros of doing business in Flagstaff is having access to university resources through NAU. Beyond working with the university itself, the entire Elemental Motors team of six engineers (five graduates and one still a student) came from NAU.

Calley is also grateful to live somewhere that he describes as geographically and culturally diverse. Born in Sedona, Calley has traveled and lived all over the world and found very few places like Flagstaff. He appreciates being in a place that is so influenced by the cultural practices and attitudes of its living, active Native American tribes. Calley also enjoys spending his days in an area with so much access todeserts, canyons, forests, and mountains.

Advice for Other Business Owners

Calley’s advice for others in business comes in two parts. The first deals with business structure: “Economy is really important. Don’t be any bigger than you have to be. Don’t spend any more money than you have to.”

After economy, Calley describes having passion for one’s work (with one small disclaimer): “It’s gotta be something you really care about… but you won’t survive without the economy first.”